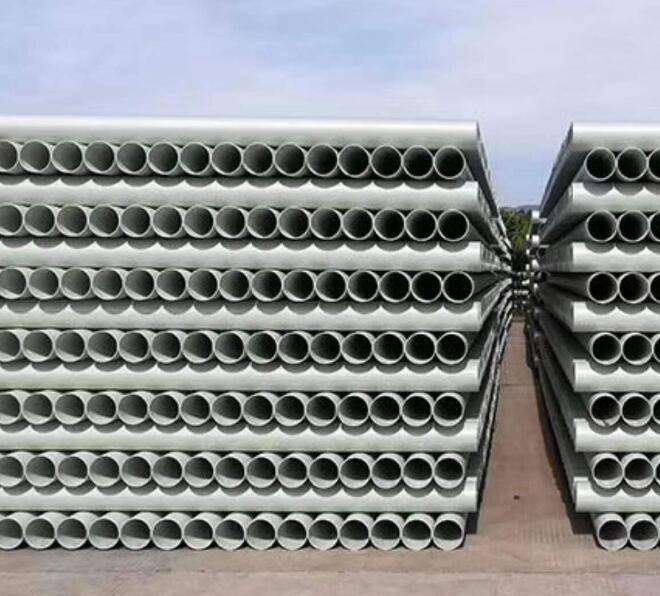

In the process of cable wiring will always use a variety of protective components, and the sleeve is more commonly used, the cable sleeve for people’s electricity safety to provide a guarantee, then the cable sleeve series performance characteristics are what? Let’s learn more about it together.

Cable sleeve series performance characteristics

(1) high strength, high stiffness. It is used for direct burial under the carriageway without adding concrete protective layer, which can speed up the construction progress of the cable project.

(2) The pipe is flexible and can resist damage caused by external pressure and foundation settlement.

(3) Corrosion resistance, long service life, and can be used in humid saline-alkali land.

(4) flame retardant, good heat resistance, can be used for a long time at 130 degrees high temperature without deformation, fire does not burn.

(6) The inner wall is smooth and not easy to scratch the cable. The design adopts socket type connection mode, which is convenient for installation and connection. The joint is sealed with a rubber seal ring to adapt to thermal expansion and contraction, and to prevent mud and sand from entering.

(7) It has good anti-external signal interference performance.

cable sleeve series laying requirements

in order to protect the cable, the cable laying in the vulnerable parts to external damage to install protective tube. The commonly used protective pipes are steel pipes and rigid plastic pipes. The inner diameter of the protective tube shall not be less than 1.5 times of the outer diameter of the cable, and the thickness of the tube wall shall not be less than 2mm. Hard plastic pipes cannot be used in places where the temperature is too high and too low. The protective pipe passing through the Foundation (including the ground or floor) shall be protected by steel pipe when the inner diameter is 32mm or less. Power cables are generally equipped with protective tubes in the following places:

(1) Cable leading-in and leading-out of buildings, tunnels and trenches;

(2) Crossing sections where cables pass through floors, walls and roads;

(3) lead to the pole or the cable laid along the wall 2m high from the ground and other parts vulnerable to mechanical damage.

The laying methods of the protection pipe include open laying along the support and bridge, concealed laying and buried laying. When buried, anti-corrosion measures must be taken, but the protective pipe buried in concrete does not need anti-corrosion. When the buried protective pipe passes through the highway and railway, the depth of the pipe top or buried person shall be greater than 1m. When the buried protective pipe is led out to the ground, the nozzle shall be at least 50mm higher than the ground, and the leading out of multiple protective pipes shall be arranged in order. The buried protective pipe shall be laid according to the shortest distance.

The diameter of the protective tube shall be calculated according to the outer diameter of the wire or cable, which shall be 1.5-2 times of the wire harness, and the abandonment and filling coefficient in the tube shall be about 40%.

The threading pipe shall not be cut and welded by electric welding, and shall be cut by machines and tools. The nozzle shall be smooth and free of burrs, and the bending arc length shall not be less than 300mm; The protective pipe shall be connected by threaded pipe fittings, and the connecting thread length shall be 4-5. The straight elbow of a single protective pipe shall not exceed two. The piping of the protective pipe shall be neat, and the nozzle shall be sealed with sealant.

Cable Sleeve Series

the above is the specific introduction of the cable sleeve series that we bring to you. The cable sleeve series is very easy to use, effectively protecting the cable equipment and ensuring the safety of electricity use. If you want to know more information, remember to pay attention to us.